ON-LINE vs OFF-LINE OIL ANALYSIS: WHO IS RIGHT?

For a comparison without prejudices between on-line and off-line systems finalized to control the main chemical-physical parameters of in-service lubricants, oil analysis for conditions’ monitoring is a very recent investigation technique -referable to Non-Destructive Tests-, very refined, coming from the original examinations aimed to Quality Control of paraffins. Those formal test methods to control products derived from oil, have been improving for more than one century as specific techniques, and have increased their number and their typology. We are speaking about “academic” methodologies, regulated by ASTM/ISO/DIN, where a very high precision is requested to prevent mass market products -the lubricants- can create mechanical damages or environmental troubles.Those tests are long, expensive, and are carried out by dedicated instruments and by qualified personnel.

Approximately 50 years ago, such a methodological approach (due to combined needs in the military field and demands for higher efficiency in the growing industrial field), has generated a few simplified analysis methods, based on variations of trends, rather than absolute values.We were at the starting phases of controls on lube oils “in service”, or “used ones”.

Sometimes we refer to those products as “exhausted”, good only for disposal; but even in those conditions, they can tell us useful and precious information about their life cycle. We are no longer interested in 3rd decimal of absolute viscosity, but instead we care about its variation by 10% -or even 20%- along the time.

The same can be stated about other key parameters, as acidity, basicity, metallic elements or additives. Those analytical determinations need to be quick, cheap and safeguard the environment.

The instruments, thanks to a dynamic combination with technicians expert in analysis and aware of the asset conditions where samples are coming from, have adapted their features to these new requirements and, following the system digitization, become user friendly.Now the same instruments are manageable also in the field, by non- specialists trained for such specific purposes.

The results of this real cultural revolution, where the oil is able to tell the criticalities of an asset exactly as the blood circulating inside human beings, are immediately felt. Several laboratories specialized in this kind of controls are born worldwide. Few cubic centimeters of in-service oil undergo 4 or 5 key tests, and give a detailed analysis of asset health conditions. Some standards are applied as such, while other – developed on purpose – are the results of specific requests. International correlation circuits among laboratories have been created, to assure the alignment of the different analysis and the relevant results.

While the industrial world goes on, somebody starts thinking how to furtherly simplify the process.Including sample collection, shipment to a lab, waiting for the response… sometimes, in critical contexts, immediacy of the response seems crucial. This is the origin of the “beyond the lab” approach, promoted by Spectro Scientific as a strategic decision, mostly based on compact, easy- to-use instruments, for a quick GO – NO GO decision directly onsite. Extremely useful in challenging situations, as nuclear plants, mines, large industrial plants far from cities.

And finally in last 10 years, thanks to the miniaturization of sensors and the easiness of digital connections, control systems are developed to be installed onboard the asset -as vibrations or ultrasonics- able to monitor real time the oil conditions through dedicated interfaces dipped in the flowing fluid. The Monitoil® system rises as a highly sophisticated investigation element, and thanks to the selection of robust and durable sensors, starts delivering precious diagnostic elements.

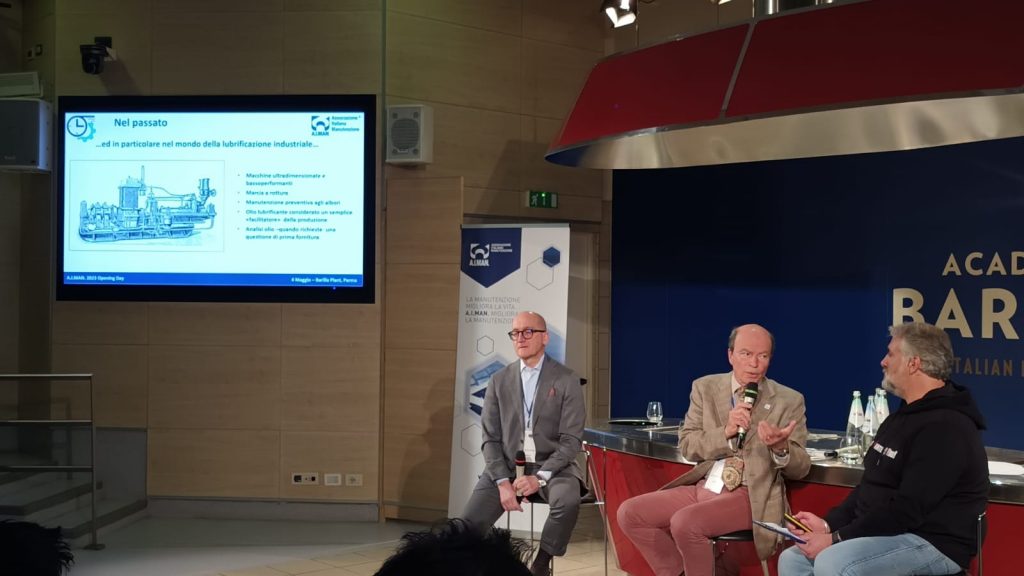

This is the summary of a dynamic speech by Adriani as AIMAN councilor, held at the end of a working session during the Opening Day on May 4th, 2023, at Academia Barilla. The works have been carried out in a refined environment, stimulating the exchange of technical – and not only- ideas, energized by the introduction from Paolo Barilla. Our mentor Alessandro Spadini has facilitated the different interventions and speeches, in the frame of an outstanding organization cared by Tim Global Media with a large young staff, reminding all of us “Maintenance (4you) is good for the entire world”; all that aiming next event https://www.aiman.com/a-i-man-sara-presente-a-euromaintenance-2023.